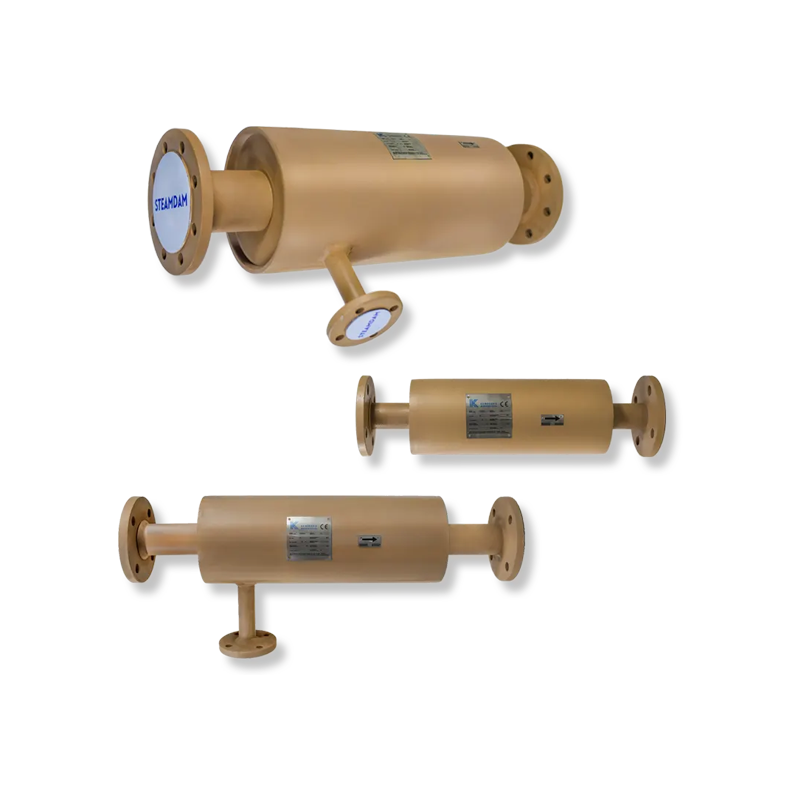

As KV Mechanical & Engineering, we offer you the LINE DEMISTER, which is innovative solution-oriented in your energy systems and designed for efficient and trouble-free operation.

With our experienced team, we aim to increase your energy efficiency while extending the life of your systems.

KV Mechanical & Engineering continues to make a difference in the sector with its experience and the importance it attaches to customer satisfaction.

Pipeline demister is the perfect solution to purify the water droplets in the steam obtained from the steam boiler. The use of quality steam means energy savings.

Achieving 100% dry steam in boilers and during transportation is impossible. Water droplets from the boiler and condensation in the pipelines form a mixture of steam and water. Typically, boiler steam is 95% dry, containing 5% water. The dryness decreases at the consumption point. A pipeline demister placed at this point increases steam dryness and reduces steam consumption.

MORE